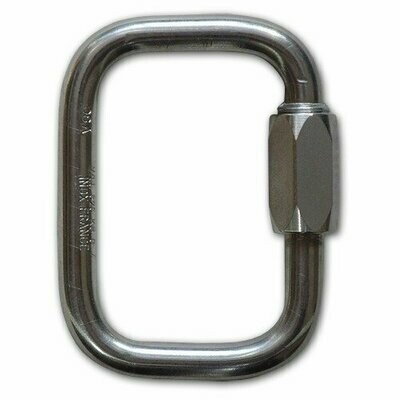

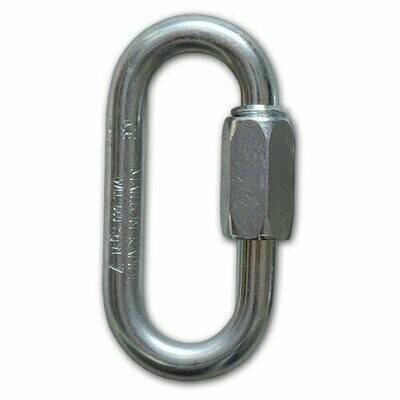

Charly Snaplock Carabiner

The Finsterwalder SNAPLOCK hang gliding and paragliding carabiner features maximum security.

5-year (2-year for hang gliders) replacement interval

With the SNAPLOCK, Finsterwalder is now also offering a paragliding carabiner with the popular twistlock whose fatigue strength was tested by an accordingly licensed institute. Until now, for karabiners with a conventional lock a guarantee could be issued for only two years respectively for a limited number of operating hours. The SNAPLOCK's design in combination with the high strength of the Titanal material now enable a guarantee of five years in mono use and of two years for the use in tandems.

Safer and lighter

The SNAPLOCK resists 14 kN without incurring damage even with open gate - this is more than four times as much as the hitherto common steel carabiners can bear. It is thus unproblematic should the SNAPLOCK once be loaded with open gate. Also the breaking load of at least 30 kN with closed gate is a new top mark. Using SNAPLOCK carabiners with only 76 g per piece instead of steel karabiners, a weight reduction at the harness of about 150 g is achieved.

Suitable not only for 25 mm webbings

The Finsterwalder SNAPLOCK is suitable for modern lightweight harnesses with a webbing width of 25 mm or less. However, it also fits into the formerly common 44 mm webbings if they can be tucked in as pictured and if the loops are long enough. This is the case if a rod with a minimum diameter of 20 mm fits through the loops.At harnesses with tight loops, the SNAPLOCK is mounted via the gate side of the carabiner (see mounting directions for harnesses with a webbing width of 44 mm).

Convenient

The single twistlock is easy to operate as the gate does not need to be pushed down to be opened. As both parts of the SNAPLOCK's locking hook are closed, the paraglider webbings do not get caught whilst hooking in and out. Anti-twist By means of its prominent nose, the SNAPLOCK can be mounted at the harness in such a way that a sidewise turning of the carabiner is reliably prevented. Additionally, there is the possibility for harness manufacturers to attach back straps above the nose. The back support can thus be drastically improved.

Overview of the Finsterwalder SNAPLOCK's most important features

- Breaking load: 3,000 DaN* (dekanewton= 10 newton ≈ 1 kg)

- Breaking load gate open: 2,000 DaN*

- Load without permanent deformation gate open: 1,600 DaN*, thus fatigue endurable despite gate play!

- Replacement interval for mono use: 5 years, unlimited hours of usage

- Replacement interval for tandem use: 2 years, unlimited hours of usage

- Drop-forged from Titanal

Weight: 76 g/pc.

Inner height: 60 mm

More information on the fatigue endurance of air sports carabiners

Paragliding carabiners are subject to permanent load changes during flight. Measurements by the DHV show that they can amount to between 10 and 110 kg and more, depending on pilot weight, pilot flight behavior and thermals, and that they can occur up to 26 times per second. Given the carabiners' high breaking load (at least 1.500 kg), such load changes should generally be unproblematic. However, conventional carabiners exhibit a construction-related peculiarity: their play in the gate. This play is necessary for the snap hook to open and close frictionless. However, the snap hook is force-locked only at weights of 30-120 kg (depending on the amount of play in the gate). As a result the pilot flies as if the carabiner lock was open within the range of the play in the gate. Since the carabiner construction - as practice and dynamic fatigue tests show - is not designed for such load cases, already the relatively low operating load during normal flight operations can lead to breakages due to material fatigue. As the play in the gate cannot be reliably limited and as it is difficult to control, we have constructed the SNAPLOCK in such a way that it is fatigue endurable also within the range of the play in the gate.

Please note: Not all carabiners are tested for fatigue endurance. Special caution is required when the carabiner manufacturer does not give information about the replacement interval. Steel is good ? The fatigue endurance of carabiners is not a question of material but a question of design! In dynamic fatigue tests, some aluminum carabiners exhibited substantially higher fatigue endurance levels than steel carabiners. Although stainless steel is generally more fatigue endurable, harder and more resistant to corrosion, the difference in strength can easily be outweighed by a larger width of the aluminum component. Due to the better strength-to-weight ratio, high-quality aluminum alloys are the standard in aircraft construction.